864 Fiber Project

RFPs

Request for Proposal (RFP)

For

Construction and Splicing Services for

MCNC 864 Fiber Overbuild Project

Click here to download the RFP

In addition, please review the below attachments for the Construction RFP.

- Attachment A: Fiber Construction Costs Form

- Attachment B: Fiber Splicing Costs for Segment Builds Form

- Attachment C: 864 Fiber Construction Project – Pricing Guidelines

- Attachment D: Anticipated Segment Completion Dates

- Attachment E: Proposal Signature Page

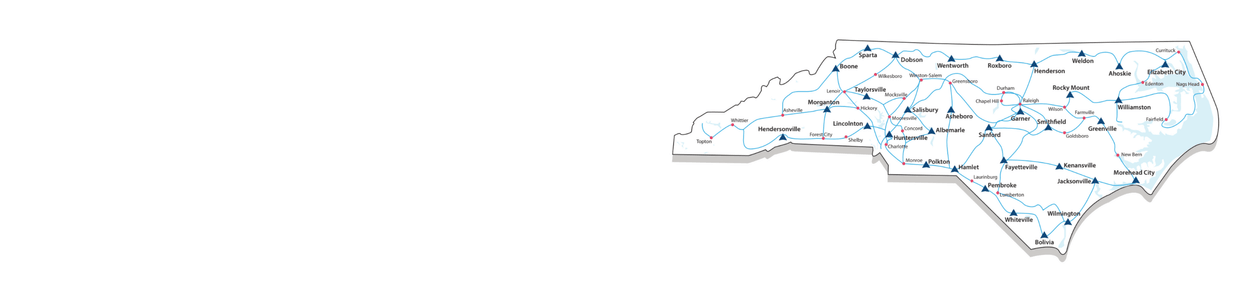

- Attachment F1: 864 Overview Map

- Attachment F2: S1-1 SAMPLE PACKAGE FOR CONSTRUCTION 4-25-2025

- Attachment F3: Duralite_3048_Unit_WEB (8) HH Spec Sheet

- Attachment F4: TLS-DS-A-314-0424_288-86 RICT ezMICRODUCT w 200um FlexRibbon Spec Sheet

- Attachment F5: HH 864 Loop Placement

- Attachment F6: MCNC 864 Construction & Splicing RFP Segments and Routes

- Attachment F7: MCNC 864 Overbuild Clt to Ral to Wilm 4-30-2025

- Attachment G: Sample Construction Agreement

- Attachment H: Sample Construction Agreement Addendum

Question #28 – Were the microducts proofed during installation?

Response #28 – We cannot confirm. However, One duct has a live 144F cable installed, the second duct has tracer wire installed and the third duct is vacant to install the new 864F. We do not have proofing verification from the initial build date in 2012, but let successful use of the other two ducts be your guide. As per Item # 1 on page 1 of Attachment C – 864 Fiber Construction Pricing Guidelines (Line-Item Quotes). We request 1) Composite labor Price for Proofing existing conduit & Fiber placement (Cost Per Foot) on column C of Attachment A – Fiber Construction Costs

Question #27 – Fiber testing: How many end to end fiber tests will be required?

Response #27 – Please refer to pricing requested on Attachment B and described on pages 3-4 of Attachment C – 6) Splicing – Contractors must provide composite costs associated with all facets of cable prep, closure installation, high volume ribbon splicing and testing per ribbon splice AND a separate line item for highly detailed fiber characterization test data packages per route span (a package for each of the 8 named route spans) – See Splicing and Test package requirements. The second/separate price requested on Attachment B is to cover highly detailed bi-directional testing for all 864 fibers on each of the 8 Routes.

Question #26 – How many new and old splice locations will be designed in, and encountered in the existing plant?

Response #26 – As per pages 3-4 of Attachment C – 864 Fiber Construction Pricing Guidelines and pages 3-4 of Attachment F6 there will be 97 new splice locations for this 864F project. This overpull/overbuild project will pass through Handholes with existing splices on the existing 144F cable but will not tie into any of them.

Question #25 – What reel lengths are being purchased?

Response #25 – They will all be 20Kft Reels except for the last Reel of the total order which will be 30Kft

Question #24 – Do existing hand holes have ground rods?

Response #24 – Yes, existing Handholes have ground rods and are tied into our locate/tracer wire and corresponding marker posts. When new Handholes are installed or changed out for larger ones to accommodate new splices as per composite pricing item #2) Handholes – Per unit pricing for the placement of approximately 386 (30″x48″x36″) handholes. Some will be new locations (no previous vault) along the MCNC route and some will be placed to “up-size” from a smaller existing HH. For clarification: there are 386 New handholes being placed under this project (289 of those are replacing old with larger new handholes, and 97 are totally new placement to accommodate splice locations) All New handholes should get approx. 6” of pea gravel in their base.

See page 2 of attachment C for break out of HH quantities.

Question #23 – Clarify 2 different completion dates June 22 – attachment D and 9/30 attachment C

Response #23 – The required completion date is June 22nd 2026 noted on page 5 and page 13 of the RFP and again on Attachment D. We apologize for the typo at the end of Attachment C. The text is in red there because it needed to be updated to match the rest of the documents. The required completion date is indeed June 22nd 2026.

Question #22 – Is there a bid bond required as well as a Surety bond, and in what amounts?

Response #22 – No Bid bond is required. But As per Page 5 of the RFP Performance and Payment Bonds Performance and payment bonds will be delivered to MCNC by the successful Respondent within ten (10) calendar days after notice of the acceptance of the Respondent’s Proposal. Such bonds shall be in an amount equal to 100% of the Contract Sum. Please see RFP Attachment G – Construction Agreement for additional information. Please pay particular attention to Article 13 Bonds.

Question #21 – Do you have an estimate for number of dig up/repairs or conduit footage to be replaced that can be factored into our overall composite rate?

Response #21 – Please refer to column F on Attachment A – Fiber Construction Costs for entering Composite pricing #4 Dig-up & Repair pricing.For further clarification these pricing Columns on Attachment A correspond to Item #s 1- 5 on pages 1-4 of Attachment C – 864 Fiber Construction Pricing Guidelines (Line-Item Quotes). For example #4 being Dig-ups and repairs and #5 being Aerial placement which only applies to the small noted footage within Segment 3 Route 7.

Provide pricing that will apply to “each” Dig up & Repair location required. Plan for the “average” Dig-up and Repair (which includes the need to access conduit for “assist pits”) to include labor to excavate & expose 10 linear feet of the existing 3way ¾” conduits. Keeping in mind there is live in-service fiber cable in one of the three conduits.

For general estimating on expected Dig up volume, consider that 80% of this 1,856,332 ft project is in rural areas with typical distances of 4,500 to 6,000 ft between existing handholes.

Question #20 – Is there a size dimension for the Dig Ups? Last time I worked a project with existing pipe the Dig Up dimensions were 4x4x4. Thanks.

Response #20 – Please plan for an “average” Dig-up and Repair (which includes the need to access conduit for “assist pits”) to include labor to excavate & expose 10 linear feet of the existing 3 way ¾” conduits. Keeping in mind there is live in-service fiber cable in one of the three conduits.

Question #19 – Will Traffic Control be provided by MCNC?

Response #19 – No. Please build Traffic Control into your composite labor pricing in Attachment A.

*Consider differing requirements between rural and heavy metro environments that this route passes through.

This 352-miles overbuild passes through 14 North Carolina Counties. 80% of this project is in rural territory where MCNC’s route far back from edge of pavement and 20% of this project is metro where professional traffic control is needed.

*Bidders should take a “prepare for the worst” approach and assume Professional Traffic Control in metropolitan areas such as Charlotte/Mecklenburg, Raleigh/Wake and Wilmington/Brunswick & New Hanover and others as needed. (Overall treat this project as 80% rural and 20% heavy metro and plan accordingly)

Question #18 – Will all required permits be acquired/provided by MCNC?

Response #18 – As per para 3 page 6 of the RFP document:

All North Carolina Department of Transportation (“NCDOT”), municipalities, railroad permits, easements, and rights-of-way permitting will be obtained by MCNC. Additional Construction permits and privilege licenses shall be obtained by the Contractor, as well as all required railroad and DOT bonds and insurance.

Question #17 – Is there a kmz for this project?

Response #17 – Yes, the KMZ is Attachment F7 on the RFP website. All Maps and attachments are summarized on page 22 (Attachment F) of the main RFP document.

Question #16 – Is per foot pricing based on fiber sequential or span footage?

Response #16 – Requested Per foot pricing should be based on span footage – Please consider requirements for placing maintenance loops, adequate splicing tails as part of the composite pricing. Reference details on pages 1-3 of Attachment C and page 7 of the RFP document.

Question #15 – Does any portion of this project fall under prevailing wage/ davis bacon requirements?

Response #15 – No, However, We expect MCNC contractors to pay their personnel appropriately to yield high quality work and performance.

Question #14 – This is set to bid 24 ct ribbon splices which takes a specialized ribbon splicer. Can this be broken down into 12 ct ribbon and spliced?

Response #14 – No.

Question #13 –Just looking at the specs from Prysmian they say max fiber length for 864 ct ribbon is 14,000′ just caught my eye, guess you can order special length.

Response #13 – Correct, this is a custom order to support this MCNC project

Question #12 –I see example PDF’s for SC-1. It has 14 reels of 864 fiber and 13 splice locations. That is correct. I think i have looked over everything and I don’t see a price for terminations. Are they going to be splice on connectors or are they cassettes or are they preterm to the 0-HH? This will add 2 splice points per segment to the splicing total.

Response #12 – Terminations will be made by splicing to pre-terminated cables at the Zero Handhole outside of the end/site locations in Charlotte, Hamlet, Wilmington and Raleigh. These addresses are yet to be determined.

Please refer to pages 3 and 4 of Attachment C for the quantity of 24 Ribbon burns and splice locations and provide pricing for these named quantities when entering your composite Fiber Splicing and Testing costs onto Attachment B. For Example: S1-Route 1-Charlotte to Polkton has 468 ribbon burns and 13 splice locations called out on page 3 of Attachment C. Please provide your Composite Fiber splicing and Bi-Di testing for that stated volume. However, we will apply this per Ribbon burn price to any “additional” splice locations that may be required on this project.

Question #11 – If 24 per burn the same question applies – curious about splice closures and trays being used.

Response #11 – MCNC uses FOSC D-600 Closures and Ribbon Trays

Question #10 – This is set to bid 24 ct ribbon splices which takes a specialized ribbon splicer. Can this be broken down into 12 ct ribbon and spliced? And… During testing, if 11 fibers in a ribbon are good and to spec and 1 fiber is not, can that fiber be separated from the other 11 and core alignment spliced separately to keep from breaking the rest and possibly having more that are affected because of this action?

Response #10 – Revised answer: **SPECIAL NOTE** Recent guidance from the Fiber manufacturer: In regard to Splicing the 24 fiber ribbons, It is acceptable for each 24-ribbon to be split into two 12 fiber ribbons and spliced 12 fibers at a time using a 200 micron splicing jig on ribbon splicing machines. Further procedural guidance pending from Prysmian. Please price the total required quantity of required splicing accordingly.

And…This is a wise question: Refer to page 7 of Attachment C. regarding field splice standards and the requirements to restore Out of Spec fibers. Additional guidance: If there are two or less OOS fibers within a given 24 Fiber ribbon, they must be documented for potential future correction when end to end OTDR testing takes place. If there are more than Two OOS fibers, the ribbon should be broken and re-spliced to achieve the best possible results. For the purposes of this bid and for uniformity’s sake, we do not want to call out separating individual fibers from the rest of the ribbon at this time.

**If each 24 ribbon is separated into two 12 fiber ribbons: In that case, if there is one OOS fiber within a given 12 Fiber ribbon, it must be documented for potential future correction when end to end OTDR testing takes place. If there are Two or more OOS fibers out of 12, then the 12-fiber ribbon should be broken and respliced to achieve the best possible results.

Question #9 – Can you provide the current duct configuration along the path?

Response #9 – Three .75” ID HDPE ducts (Tri-duct). One occupied with existing live MCNC 144F cable and the other two are vacant.

As per Attachment C – 864 Fiber Construction Pricing Guidelines (Line-Item Quotes) …

…proofing and placement of approximately 1,856,332 ft (351.58 miles) of .50” O.D. 864F Prysmian non-armored ribbon cable (24 Fibers per ribbon) into existing empty .75″ I.D. conduit

Question #8 – If a repair is needed on the conduit, who is providing the duct material? If it is the contractor do you have a manufacturer and part number where it can be purchased?

Response #8 – MCNC will provide conduit needed for repairs.

Question #7 – In response to the 864 RFP, Is there another materials RFP coming soon here after?

Response #7 – No

Question #6b – Are we allowed to work all 3 segments simultaneously with multiple crews in each segment?

Response #6b – Working multiple segments simultaneously is advised and highly recommended to meet production goals and the stated completion timeframe.

Question #6a – Can you confirm the size of the pipe?

Response #6a – 0.75” ID conduit As per Attachment C – 864 Fiber Construction Pricing Guidelines

(Line-Item Quotes)

1) Proofing and Placement – Per foot pricing for proofing and placement of approximately 1,856,332 ft

(351.58 miles) of .50” O.D. 864F Prysmian non-armored ribbon cable (24 Fibers per ribbon) into existing empty .75″ I.D. conduit.

Question #6 – Do you have a preference of installation method of the fiber? (i.e. jetting, pulling or tugging)? Are either methods acceptable?

Response #6 – Consider “pulled” to be a general term such as “installed.” The long spans of this overbuild should all be installed with fiber blowing equipment. Fiber Cable is to be installed using best practices to meet or exceed the need of the overall quality, production schedule and especially to ensure max pulling tension is never exceeded, etc.

Question #5 – I see you posted spec sheet of an 864 micro cable. Is the current duct that is being used standard duct? If so, what is the diameter of the current duct? If standard duct, are you going to be placing micro duct inside before jetting the micro cable?

Response #5 – As per Attachment C – 864 Fiber Construction Pricing Guidelines (Line-Item Quotes)

1) Proofing and Placement – Per foot pricing for proofing and placement of approximately 1,856,332 ft

(351.58 miles) of .50” O.D. 864F Prysmian non-armored ribbon cable (24 Fibers per ribbon) into existing empty .75″ I.D. conduit.

Question #4k – Can you quantify how many new hand holes vs how many replace handholes?

Response #4k – For clarification: there are 386 new handholes being placed. (289 of those are replacing old with larger new handholes, and 97 are totally new placement to accommodate splice locations).

Question #4j – Who is responsible for permitting?

Response #4j – As per para 6 page 6: All North Carolina Department of Transportation (“NCDOT”), municipalities, railroad permits, easements, and rights-of-way permitting will be obtained by MCNC. Additional Construction permits and privilege licenses shall be obtained by the Contractor, as well as all required railroad and DOT bonds and insurance.

Question #4i – Do you require all new fiber to be pulled as the print states?

Response #4i – Consider “pulled” to be a general term such as “installed” The long spans of this overbuild should be installed with fiber blowing equipment. Fiber Cable is to be installed using best practices to meet the production need of the overall quality, production schedule and ensure max pulling tension is never exceeded, etc.

Question #4h – How are we compensated for traffic control?

Response #4h – Please build Traffic Control into your composite labor pricing in Attachment A. *Consider differing requirements between rural and heavy metro environments that this route passes through. This 352 miles overbuild passes through 14 North Carolina Counties. 80% of this project is in rural territory where MCNC’s route far back from edge of pavement and 20% of this project is metro where professional traffic control is needed.

*Bidders should take a “prepare for the worst” approach and assume Professional Traffic Control in

metropolitan areas such as Charlotte/Mecklenberg, Raleigh/Wake and Wilmington/Brunswick & New

Hanover and others as needed. (Overall treat this project as 80% rural and 20% heavy metro and plan

accordingly).

Question #4g – What do we do with the removal of the existing hand hole?

Response #4g – Please include disposal of the old Handholes removed as part of your “HH

Upgrade/replace existing” pricing

Question #4f –How much pea gravel is required in the existing hand holes? How many existing hand holes require new pea gravel?

Response #4f – You should place between 2” to 3” of fresh pea gravel in the floor of existing hand holes. Every pre-existing handhole this project touches should be “refreshed” with 2 to 3” of new pea

gravel as we access & pull through. There are 372 existing handholes that will remain in place along this project path. We want to “refresh” those with 2”-3” of new pea gravel. For clarification: there are 386 New handholes being placed (289 of those are replacing old with larger new handholes, and 97 are totally new placement to accommodate splice locations) All “NEW” handholes should get approx. 6” of pea gravel in their base.

Question #4e – Are the existing hand holes buried or flush mount?

Response #4e – MCNC’s existing Hand holes are Flush mounted (at grade)

Question #4d – Do all fibers need to be pretested or just (1) per ribbon?

Response #4d – In regard to Pre-testing of the new fiber reels before installation, 1 fiber per ribbon is

acceptable

Question #4c – What is the depth of the existing conduit?

Response #4c – Presume the “Average” depth of existing coupler locations on the conduit is 36” to 48”

Question #4b – What is the linear distance for a dig up and repair? For example, what if the duct is packed with dirt for 30 linear feet vs just a damaged coupler?

Response #4b ��– Please plan for an “average” Dig-up and Repair (which includes the need to access conduit for “assist pits”) to include labor to excavate & expose 10 linear feet of the existing 3way ¾” conduits. Keeping in mind there is live in-service fiber cable in one of the three conduits.

Question #4a – How old is the existing duct path?

Response #4a – Approximately 15 years

Question #3 – Do we assume that our proposal is to include standard M.O.T. being signs & cones only? Police and Certified Traffic Control Companies have very rarely been required on any of our projects throughout NC over the last 12-18 months other than in areas damaged by Hurricane Helene, and in a couple of major metropolitan cities and have been paid at actual cost by project owner? Please advise as I’ve not seen it referenced in the documentation provided by MCNC, possibility my old, tired eyes missed it.

Response #3 – Simple MOT (Maintenance of Traffic) signage will not suffice based on differing requirements between rural and heavy metro environments that this route passes through. Bidders should take a “prepare for the worst” approach and assume the need for Professional Traffic Control in any metropolitan area such as Charlotte/Mecklinberg, Raleigh/Wake and Wilmington/Brunswick & New Hanover and others.

Question #2 – I received this RFP but one of the files won’t open, “Attachment F7 – MCNC 864 Overbuild Clt to Ral to Wilm 4-30-2025.kmz”.

Response #2 – Attachment F7 – MCNC 864 Overbuild Charlotte to Raleigh to Wilmington 4-30-2025.kmz”. This file requires Google Earth to be loaded on your computer or another application that allows viewing of KMZ files. This attachment is a basic KMZ map file of the over build route. It should first be downloaded and then viewed with Google earth.

Note: Attachment 7 is a Google Drive link because our site does not allow us to upload kmz files in the same way as the others. You should be able to click “download” after the link opens.

Question #1 – Will there be any Fiber Huts required on the 864 Fiber Project?

Response #1 – No, there will be no new Fiber Huts required on the 864 Fiber Project